10 mistakes made while installing the underfloor heating system

Too high or too low room temperature, leaks, cracked tiles - these are only a few possible effects of various types of mistakes made while planning or installing the underfloor heating system. Malfunctioning floor heating is usually the result of careless installation or adopting improper solutions. Today we will look at 10 common mistakes made when installing the underfloor heating system.

1. Lack of appropriate documentation

The lack of a proper design while installing any heating system may have disastrous effects. In the case of underfloor heating, the layout as well as the shaping of the heating pipes must be adjusted to the parameters of the supply water in the heating system, the screed thickness, the type of floor covering and heat demand. Lack of reliable documentation does not only lead to higher costs of maintenance, but it also spells trouble in case of heating system failure. It is important to document the actual layout of the heating pipes on the room plan, especially in the area between the rooms, under the windows and near the walls. If we know the actual dimensions of the loops, we can avoid damaging them accidentally while installing threshold strips or other elements that require drilling in the floor.

2. Wrong order of installation works

Underfloor heating system must be installed in correct order. It should start after other systems have been laid, otherwise the heating pipes and other elements of the heating system may be damaged. Manifold cabinets and manifolds should be installed before laying the pipes. The floor heating distributor box should be installed as close to the underfloor heating system as possible, rather than in a remote boiler room. It is worth remembering that it is impossible to install the whole underfloor heating system when the house is at the open shell stage without the windows and doors. These elements are necessary to prevent draughts when the screed is setting. Thanks to this, we may prevent excessive drying of the screed surface.

3. Improperly prepared ground

Some problems may also result from poorly executed construction works. Before installing the underfloor heating system, the floor must be prepared properly. What are the most common mistakes which bring about unpleasant consequences? The three most serious ones concerning the the floor preparation are listed below.

Further layers of underfloor heating system such as thermal insulation, heating pipes and concrete screed cannot be laid on uneven surfaces. Careless preparation of the base, skipping the levelling and cleaning stage means that the thermal insulation boards will not adhere well and will not provide a stable support for the screed, which may lead to cracking. In places where the screed cracks, there is a risk that the heating pipes will be damaged. Furthermore, uneven ground requires different thickness of the screed on the floor. That is why it is so important to level the surface before laying the insulation.

4. Incorrect connection of pipes in loops

Heating pipes form the so-called heating circuit, the length of which should not exceed 100 m depending on the diameter of the pipes used. Therefore, during installation work, make sure that the installer does not make longer heating loops. It is also worth remembering that each loop should be made up of one continuous length of pipe. Connections are allowed in the event of pump damage and with the use of special repair couplings which can be covered with concrete. To avoid problems, it is therefore necessary to select the pipes in such a way as to avoid connections in the places which will be covered with the screed. Such connections are the most vulnerable points because dirt easily deposits there, which results in defects. Failure to follow the instructions will increase the hydraulic resistance, resulting in insufficient heating of certain areas of the floor.

5. Failure to secure the heating pipes to the floor properly

The heating pipes which will carry water must be firmly attached to the ground. First, a special pipe-positioning foil with anchor mesh should be placed on the polystyrene layer. Next, the pipes are secured to the foil using the clips included in the underfloor heating system set. If the pipes are not fastened properly, they can disconnect from the ground while the screed is poured on the ground. In addition, if the system includes copper components, pipes should not be laid directly on concrete as they may corrode. Copper pipes must be protected with an additional layer of plastic. An alternative is to use pipes made of different materials such as plastic or multi-layer pipes. It is worth choosing high-quality products that exclude the risk of damage.

6. Lack of proper expansion joints

The floor in which the heating pipes are embedded requires proper expansion joints. The heating surface expands due to the heat from the pipes, which is why it is necessary to make expansion joints. If the room is large or has an unusual shape, it is necessary to plan additional expansion joints in the screed. The lack of such gaps or making them only in the floor covering rather than through the screed can lead to scratches and cracks. It is important to arrange the heating pipes in such a way that the expansion joints do not cross them.

7. Carelessly applied screed

One of the last stages of installing the underfloor heating system is to bury the heating pipes in screed. At this stage, it is recommended to supervise the work of people who pour the concrete to avoid damage to the heating pipes or covering the gaps or expansion joints. It is possible to lay the floor covering only after the screed has dried properly and reached its optimum parameters. In order for the concrete to set well, the surface must be prevented from drying excessively. After about 21 days you need to preheat the screed so that the remaining moisture is removed.

8. Choosing improper floor covering

Unfortunately, not every material is suitable for covering the floor if we decided to install the underfloor heating system. Therefore, the question of what material will be the best is one of the key questions when it comes to the installation of hydronic underfloor heating. The type of floor covering determines the heating efficiency. For example, a change from ceramic tiles to floor panels will decrease the heating efficiency two times, which in turn will lead to problems with maintaining the pre-set temperature when the outdoor temperature is low. A common solution in this case is to increase the supply temperature, which is not a good solution because it can damage the heating system as well as the floor covering itself. The types of materials used while installing the underfloor heating system are shown in the graphic below.

9. No pressure test or conducting it improperly

Before laying the screed, the system must be filled with water in order to check if the pressure in the system has not dropped excessively after a few hours or even a day. At this stage, it is easier to detect and remove leaks than after the pipes have been covered with concrete. The pressure test should be carried out when all heating circuits are filled with water. Sometimes installers give up this activity altogether or fill the pipes with air instead of water. Conducting the pressure test improperly may have serious consequences. It is essential to make sure that there are no leaks before we lay the screed. In the event of an undetected leak, the system can be seriously damaged and repair will be difficult and expensive.

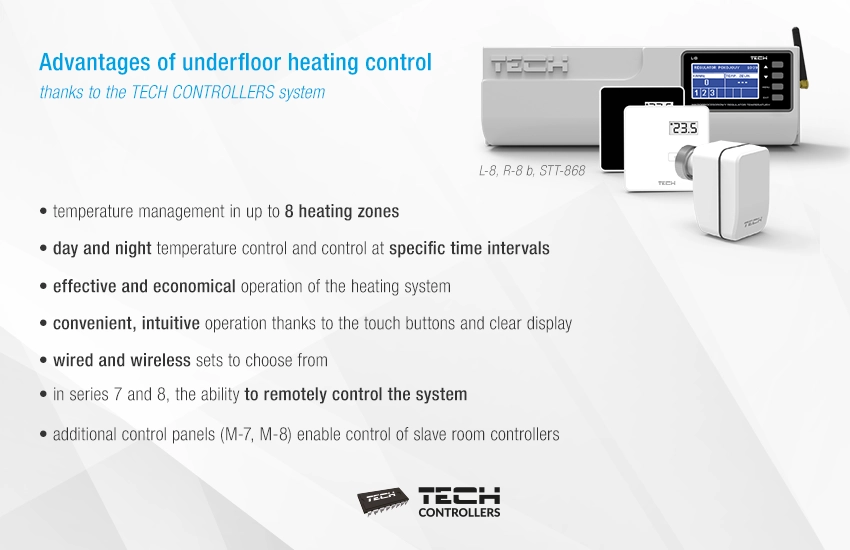

10. Not using underfloor heating controllers

When installing the underfloor heating system, it is a mistake to limit yourself to the simplest solutions and decide not to use controllers for managing the underfloor heating. Neglecting the underfloor heating control leads to significant energy loss, which results from high thermal inertia of the system. Our modern underfloor heating controllers from the 5, 7 or 8 series will allow you to enjoy the advantages of installing this type of heating in your home as well as reasonably manage your home budget.

Costly mistakes when installing the underfloor heating system.

Installing underfloor heating is a perfect solution for those who love comfort and convenience. It is worth remembering, however, that only a well-designed and well-made system will ensure the expected results. Mistakes made while laying the underfloor heating system affect the failure rate and reliability of the entire system. By choosing proven solutions, competent contractors and reliable manufacturers, you will be able to enjoy a warm floor for many years.